Power control and switching solutions: From 5 mA to 50 kA

Astrol is a Switzerland based innovator and manufacturer of state-of-the-art power control and switching solutions. We design and manufacture diverse electronic products such as solid-state circuit breakers (AC and DC), solid-state power switches, Gate drive unites, isolated power supplies and customized electronics. Our focus lies on engineering, power switching and current interruption solutions in the medium voltage range, from optimized gate drive units to fully integrated solutions of up to 100kV.

Astrol is a diverse and multidiscipline company, in terms of technology as well as in terms of projects. We manage small electronic projects, from bicycle computers of a few milliamp (mA) to thyristor switches or GCT switches for 20 or 50 kA with 10 kV driving voltage.

We have software, analog and digital engineering in the low, medium, and high-power range. Product application varies from fusion, heat storage, smart AC and DC grids to railway rolling stock and infrastructure. It is clear that an engineer at Astrol has a very versatile job.

An engineer at Astrol has a very diverse field of work.

Large variety in engineering projects

A finished product could be “just” an electronic part like a PCB, which can be a two-day project. It can also be a complete finished device like a medium voltage, three phase AC breaker, for instance, which is a two-year project. Besides, our high-quality products are designed, manufactured, and tested in our production location and high voltage test laboratory in Othmarsingen.

Thanks to their ability to withstand harsh conditions and extended temperatures, our products have a long lifetime. Owing to our highly educated, experienced team, and efficient procedures, our customers are assured of premium quality products.

How we work

Investigate customer request

Customer approaches Astrol with an idea or problem they are facing.

Set-up project team

A project team is formed with colleagues from the following departments: mechanical engineering, software engineering, electronic engineers, production engineers, test engineering.

Review phase

Engineering department reviews the request and checks the possibilities. If there is an existing design that we can adapt, we will use that. If not, we will create something from scratch.

Design phase

Starting to design the product. We use different tools for the electronics, software and mechanical parts. (Altium, cad software tool for schematic drawings and PCB drawings. Solid edge, a mechanical CAD software combined with an SQL system. )

Production phase

We send all the information to our suppliers for PCB assembly and the production of (some) mechanical parts. After receiving these electronic parts, we test (production or type tests) them. We test if the mechanical parts fit, if not, we adjust them. At last, the electronics are integrated into the mechanics, and we build/assemble the complete system.

User Manuals

Create/write user manuals

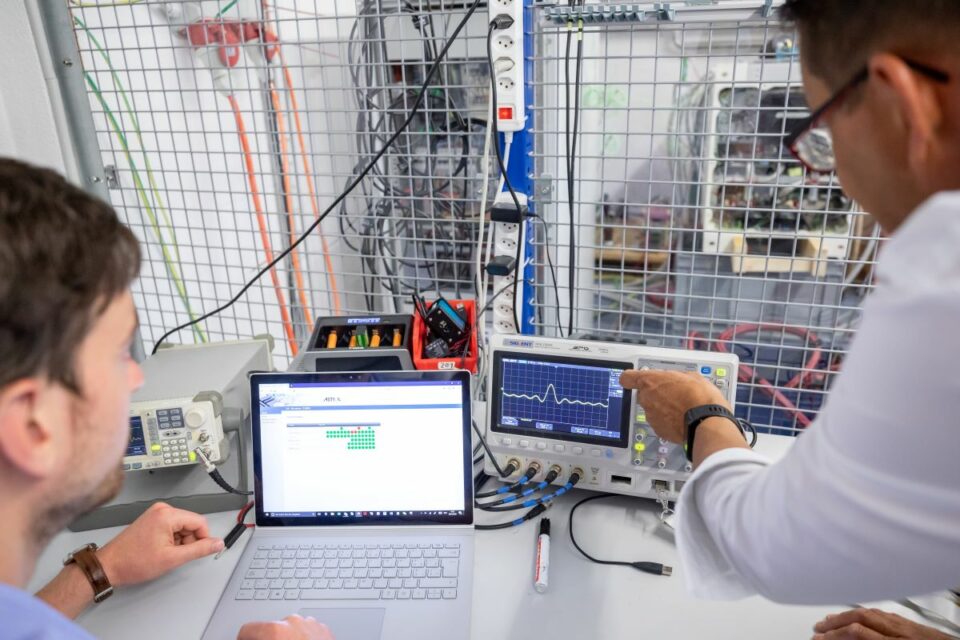

Test phase

System testing is done in our in-house high voltage, high current test laboratory or at customer site.

Maintenance, repair phase

When something does not work correctly at customer site, we make sure this is solved as soon as possible. Depending on the error the required specialist will take care of this, either remotely or at customer site.

High voltage and high current test lab

High voltage test lab

High current testing

Astrol has a DC current source which is capable of supplying up to 5.000 A continuously and up to 30.000 A short-circuit simulation. This is used for testing our solid-state DC breakers.

An example: testing a thyristor switch for discharge applications

To test the working of the thyristors we use the following test: We have a capacitor charged for instance 1000 volts or 10,000 volt and we discharge this capacitor into a load. Typically, we have an inductance, a few micro-Henry, and depending on the test a few milli Ohm or Ohm for the load resistance and then we discharge this capacitor into this load.

We want to see how the thyristor is working, everything must switch on at the same time.

If we have for instance a serial connection of several thyristors, we must be sure that all of them are switching on at the same time. This is especially important when we have high di/dt GCT switches like the a TH91.

Testing on-site

In some cases, Astrol cannot do the testing because it is not possible to have required amount of power, in some cases one million A in a load. In those cases, we send the switch to the customer and perform the testing on-site.

We will either go to the customer to perform the testing or we send the test protocol to them. The customer performs the testing, and we review the results. For many high di/dt projects the testing occurs in this manner.

The engineering team

- Administration

- Engineering; Mechanical | Software | Electronic | Production | Testing